Why Your Risk Register Software Should Be Talking to Your Silica Dust Monitors

The last couple of years have seen increased attention from the media, unions, and regulators on workplace hazards specifically on respirable crystalline silica in Australia. States have increased compliance requirements and with a potential national ban on engineered stone, the burden of proof is shifting. It is no longer sufficient to state that silica exposure is being managed, you must demonstrate it.

Most organizations are falling short in connecting exposure monitoring with their Risk Register software, not in monitoring the air.

Silica exposure incidents are a health hazard and a strategic business risk, yet the air monitoring output sits in isolation.

Lack of an integrat approach to monitoring and mitigating risks is outdate and no longer compliant.

The lack of visibility of risks and their control measures and the absence of an automated system to monitor and document control measures is non-compliance.

Compliance and risk management in Australia have evolved to a stage where regulators no longer focus on the mere existence of control measures. They require evidence that control measures are implement, assess for effectiveness, and subject to continuous improvement.

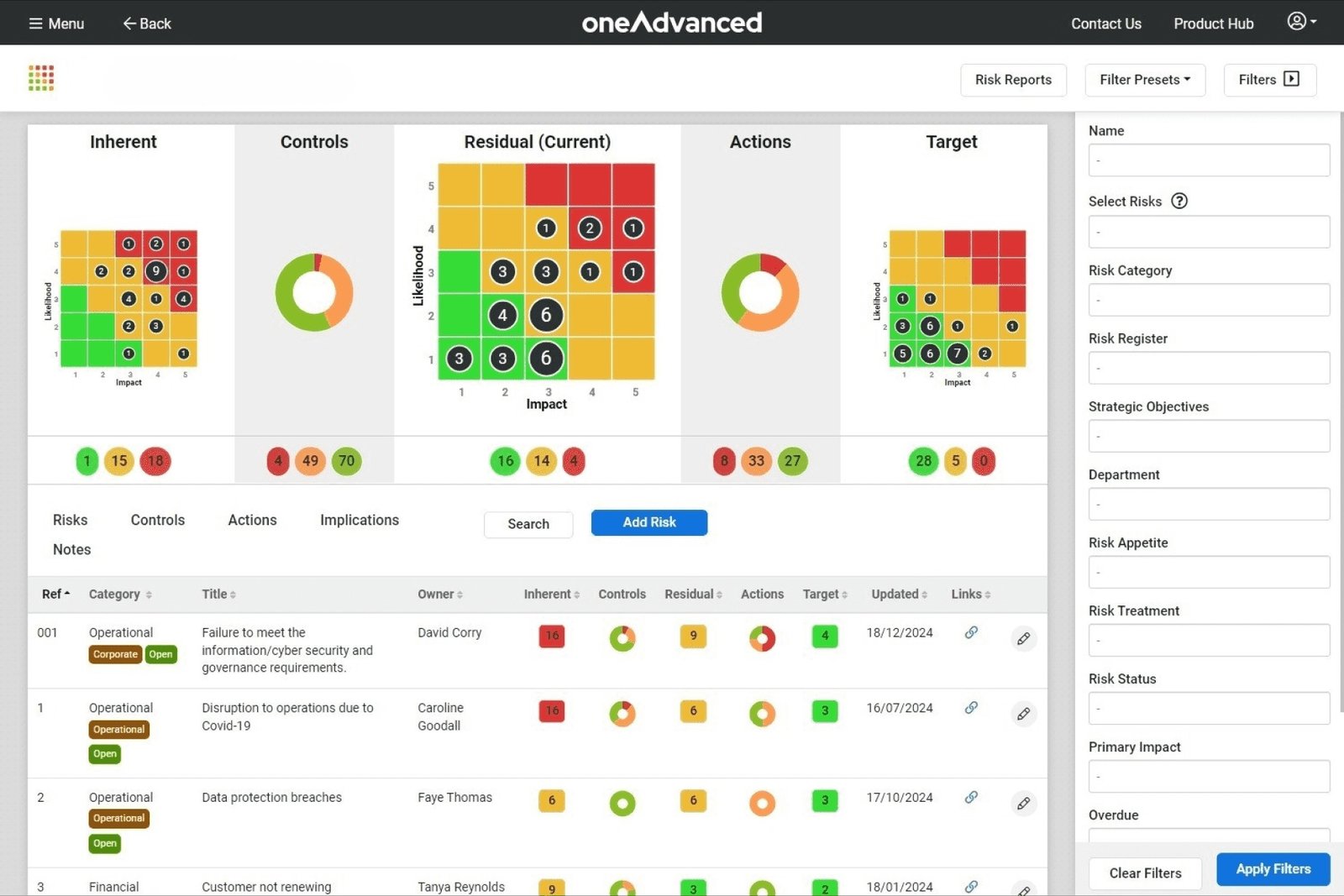

Integrated risk management and compliance tools should facilitate in real time the oversight of risk exposure of workplace hazards, including silica dust monitoring, associated with specified roles, locations, and tasks.

Assign controls with accountability and due dates

Assign accountability and due dates for each control.

Use actual exposure data to evaluate the effectiveness of the control.

Escalate risks if monitoring thresholds are breach.

What’s missing? Automatic incorporation of air monitoring data into the risk review cycle.

Noise Without Integration

What happens when your air sampling contractor reports a silica concentration of 0.07 mg/m³—above Safe Work Australia’s exposure standard of 0.05 mg/m³? That report might end up in compliance folder, trigger a reactive PPE response, or sit in someone’s inbox.

But does it:

Trigger a review of the residual risk rating in the Risk Register?

Notify supervisors or site managers?

Link to incident records, health surveillance logs, or engineering control reviews?

Show up in audit dashboards or board reports?

No? Then your organisation isnt capturing the full value of its monitoring or software.

Integrating Monitoring Data Into Your Risk Framework

Newer Risk Register platforms in Australia—Lahebo, Skytrust, and Vault—let users upload documents, attach data and set up automated workflows. Innovative WHS teams are using these to:

Link risk items using hygiene monitoring results.

Auto generate risk score updates when monitored exposure levels cross thresholds.

Auto generate review reminders when air monitoring indicates repeated exceedances.

To the same risk entity, coordinate health monitoring records with actions from silica-related training.

This turns the record from a simple logbook into a powerful decision tool.

Keeping Legal Risks at Bay

Silica-related claims involve health risks, but they may also come with legal claims and reputational risks. Enforcement actions due to poor risk management of silica hazards have been taken against Queensland, New South Wales, and Victoria.

If a regulator gets to your worksite, they will be asking:

What controls have been established, and how are they reviewed?

What exposure monitoring data do you hold, and how is it connected with your documented risk profile?

If your risk management register can’t provide answers to these questions when they are asked, you are legally and socially exposed.

Looking Ahead: Linking Silica Risk to Other Systems

Silica risk is not just a compliance issue; it deals with operational integrity as well. Dry cutting and other poor maintenance practices may indicate an issue with maintenance schedules and water suppression systems.

By using silica exposure as a monitored risk in your register, you can start to map the core issues that link to asset performance and potentially to your ESG reporting.

This is one of the aspects of modern risk software doing its best work—connecting WHS, operations, and the visibility of the executives.

Concluding Remarks

Monitoring air quality for compliance with silica dust regulations is one of the most important compliance tasks to complete. However, if this data is not included in your Risk Register, then your system is not complete.

Australian organisations should work to improve their reporting, going from a passive stance towards a more active integrated risk system. With air monitoring, the data shouldn’t be stored in a passive manner, but should be fully integrate as a core factor for scoring, escalating, and controlling risks.

Your Risk Register software should not just be a database. It should act as the command and control centre.