Enhancing Product Protection with Custom Foam Inserts for Boxes

Introduction

In today’s fast-paced world of e-commerce and industrial shipping, protecting products from damage has become more important than ever. Whether it’s delicate electronics, medical devices, or high-value jewellery, ensuring items arrive safely reflects directly on a brand’s reliability and professionalism. Among the many packaging innovations available today, foam inserts for boxes have emerged as one of the most efficient and adaptable solutions.

By combining flexibility, strength, and sustainability, foam inserts—especially those made from polyethylene packaging materials—offer superior protection without compromising efficiency or cost. These inserts are designed to absorb shock, reduce vibration, and keep products securely positioned during storage and transit.

Understanding Foam Inserts for Boxes

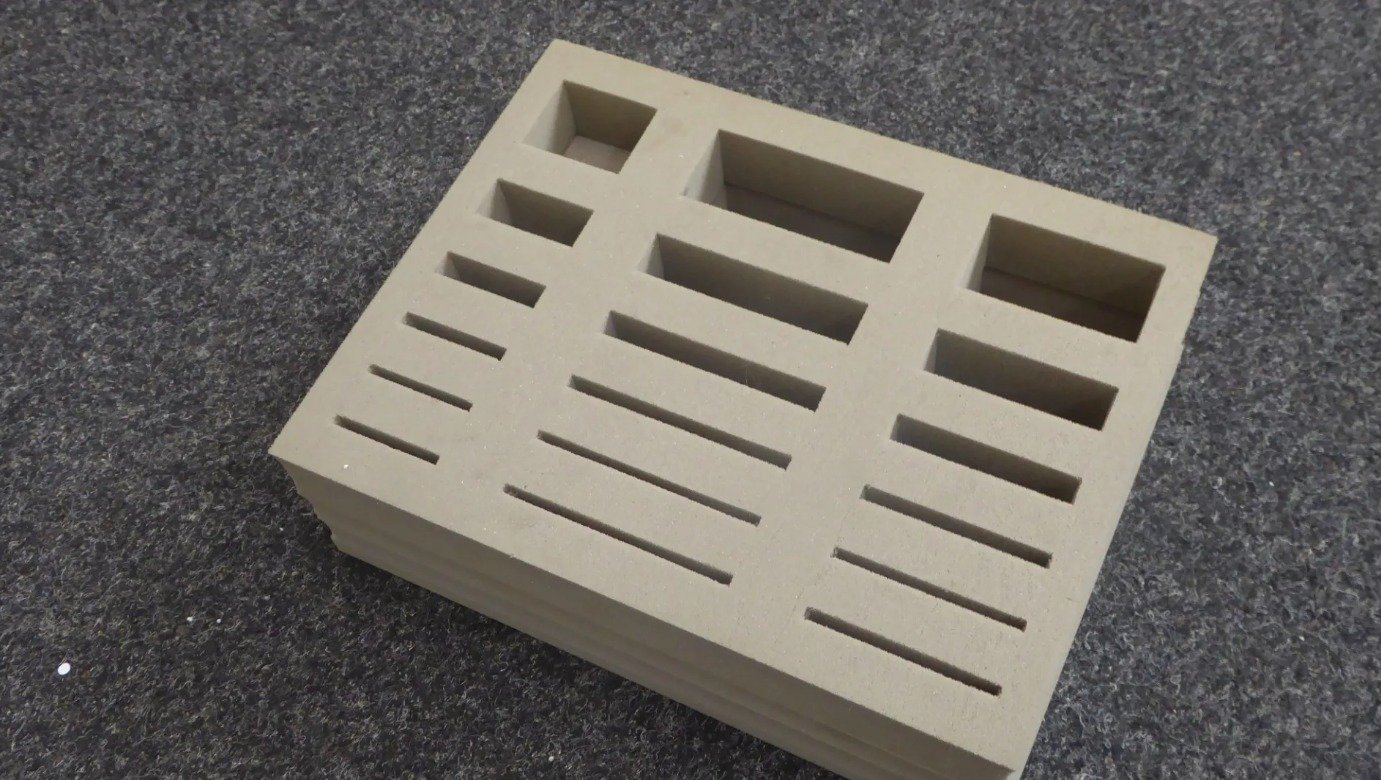

Foam inserts are precisely engineered cushioning materials placed inside boxes to protect goods during shipping and handling. They are custom-cut to fit the shape, size, and fragility of specific items, ensuring that every product remains firmly in place.

Common foam materials used in the industry include:

- Polyurethane Foam – lightweight, flexible, and ideal for delicate items.

- Polyethylene Foam – durable, impact-resistant, and perfect for industrial or heavy-duty applications.

- Polystyrene Foam – rigid and insulating, suitable for temperature-sensitive or high-strength packaging needs.

Among these, polyethylene packaging stands out due to its excellent resilience, reusability, and moisture resistance, making it ideal for both single-use and long-term shipping applications.

The Evolution of Protective Packaging

The concept of protective packaging has evolved significantly over the decades. In earlier times, products were wrapped in straw, cloth, or paper—materials that provided minimal cushioning and no real protection from impact. With the introduction of corrugated cardboard in the late 19th century, packaging became lighter and more efficient, but fragility remained an issue for delicate goods.

The 20th century brought new materials such as expanded polystyrene and foam-based packaging, transforming how industries approached product safety. Modern foam inserts for boxes now combine advanced engineering and material science to deliver maximum protection with minimal environmental impact.

Companies like Advanced Protective Packaging in Manchester have been at the forefront of this evolution, offering custom-designed foam packaging solutions that cater to specific industry requirements—from electronics and ceramics to medical instruments and automotive parts.

Benefits of Using Foam Inserts for Boxes

Superior Protection and Shock Absorption

Foam inserts are designed to cushion items from external shocks, vibrations, and sudden impacts. The dense yet flexible structure of polyethylene packaging ensures that even fragile products remain unharmed during long journeys or rough handling.

Custom Fit for Every Product

One of the greatest advantages of foam inserts is customisation. Using precision cutting and computer-aided design (CAD), manufacturers can create foam inserts that perfectly fit the dimensions of each product. This eliminates movement within the box and provides professional presentation.

Lightweight and Cost-Effective

Unlike wooden or metal packaging, foam inserts are incredibly light, reducing shipping costs while maintaining structural integrity. They also help businesses save money by minimizing product returns due to damage.

Clean, Dust-Free, and Reusable

Modern foam packaging materials are clean and dust-free, which is especially important for industries like medical equipment and electronics. Polyethylene packaging is also reusable and recyclable, making it an environmentally responsible choice.

Professional Presentation

Apart from protection, foam inserts also enhance the unboxing experience. Many premium brands use custom foam inserts for boxes not only for safety but also to give customers a sense of quality and professionalism when they open the package.

Polyethylene Packaging: The Smart Choice

Polyethylene foam packaging is particularly valued for its versatility and performance. It’s tough enough to withstand multiple drops yet soft enough to avoid scratching delicate surfaces. Its closed-cell structure prevents moisture absorption, making it perfect for environments exposed to humidity or temperature fluctuations.

Industries that frequently use polyethylene foam include:

- Electronics and Computing: to prevent static damage and physical shock.

- Jewellery and Watches: to cushion and protect valuable, fragile items.

- Medical and Laboratory Equipment: for sterile and precise packaging requirements.

- Automotive and Machinery Parts: where impact resistance is crucial.

Furthermore, polyethylene foam can be laminated, die-cut, or combined with other packaging materials like cardboard and corrugated boxes for a complete, multi-layered solution.

Sustainability in Foam Packaging

Sustainability is now at the heart of modern packaging design. Manufacturers are increasingly focusing on eco-friendly materials that maintain high performance while reducing environmental impact. Recyclable polyethylene packaging fits perfectly into this green initiative, as it can be reprocessed and reused across multiple shipping cycles.

New innovations in biodegradable foams and plant-based polymers are also reshaping the protective packaging industry. These materials decompose naturally without leaving harmful residues, helping businesses reduce their carbon footprint and meet regulatory requirements.

The Role of Custom Design and Innovation

What sets today’s foam packaging apart is the integration of technology and design precision. From 3D printing prototypes to AI-assisted packaging design, companies can now produce highly efficient protective inserts in record time.

Custom foam inserts are created to match each product’s exact shape, weight, and fragility level, ensuring every item receives optimal cushioning. Businesses benefit from faster turnaround times, reduced waste, and enhanced packaging consistency.

In addition, many manufacturers now combine foam inserts for boxes with smart packaging technologies such as embedded sensors that track temperature, humidity, or shock levels during shipment—a major advantage for sensitive goods like pharmaceuticals or electronics.

Why Businesses Choose Professional Foam Packaging Suppliers

Partnering with an experienced packaging provider ensures quality and peace of mind. Companies like Advanced Protective Packaging in Manchester have been designing and manufacturing bespoke packaging for over 30 years, offering complete solutions that include:

- Box and Carton Supply: Strength-matched to foam fitments.

- Bespoke Design Consultation: Expert advice on material choice and packaging layout.

- Complementary Products: Tapes, bubble wrap, and corner protectors for full packaging systems.

- Eco-Friendly Options: Sustainable materials and low-waste production processes.

By sourcing all packaging elements from one supplier, businesses streamline their operations, reduce paperwork, and achieve better inventory balance.

Conclusion: The Future of Foam Inserts and Polyethylene Packaging

The journey of protective packaging—from straw-filled crates to sophisticated foam inserts for boxes—reflects how far technology has advanced to meet modern challenges. Today, packaging is not just about containment; it’s about delivering efficiency, safety, and sustainability.

With continuous innovations in polyethylene packaging and the growing demand for eco-conscious materials, foam packaging solutions are set to become even smarter, lighter, and greener. Whether you’re an electronics manufacturer, a medical equipment supplier, or a retail business shipping fragile products, investing in quality foam inserts ensures your items stay secure and your brand maintains a reputation for excellence.